A photo series of our restoration process from the home workbench during COVID19

Just before the stay-at-home order went into effect in Chicago, we sold this piano. We figured it was a good time to properly document our approach and technique for restoring a Wurlitzer 200 series piano. This one started off in very rough cosmetic condition, but looked promising on the inside. Pour yourself a coffee/bubbly water/beer and get ready for some scrolling! Lets start at the beginning:

Refinishing the base:

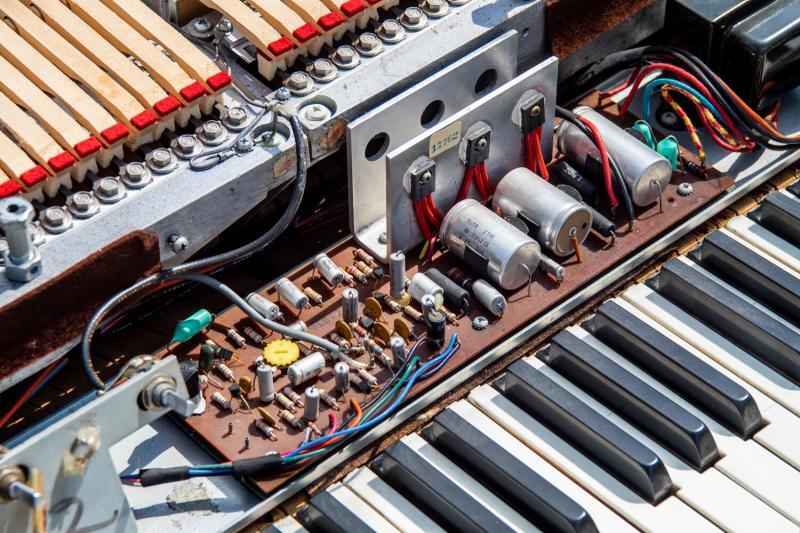

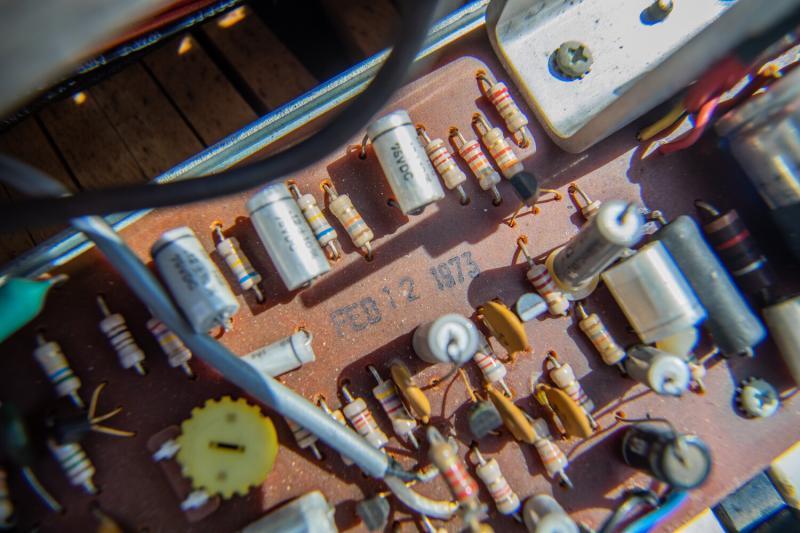

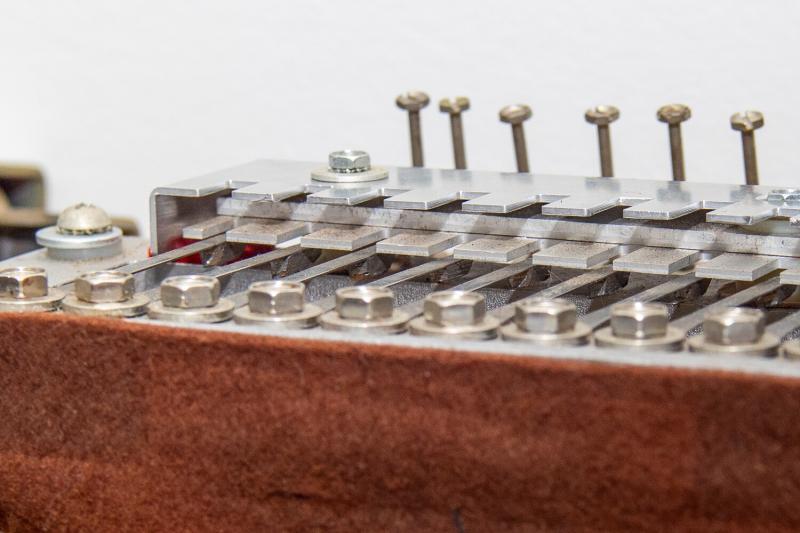

Mechanical Restoration:

The finished product: a 360 view.

Reassembly and Completion:

At this point, you may be wondering how it sounds. We got you. Enjoy these recordings of the finished instrument!

Supertramp – Take the Long Way Home

Kimbra – Wandering Limbs

Vulfpeck – Sky Mall

Alley Photoshoot (just for fun):

I’ve always wanted to snap some photos of an instrument in my alley and this seemed like the perfect opportunity. This mural (by Chicago artist Sick Fisher) provided a nice colorful backdrop. It also features a couple cameos from assistant tech and all around sweetie Tuff Guy the cat.

Hopefully this gives you some insight into our restoration process, techniques and philosophy. If you’ve made it this far, nice job!

All photos shot “on location” by Mike at his house in Chicago. Audio samples performed by Matt Blocher and recorded DI at the Chicago Electric Piano Company.

Got a Wurlitzer in need of repair? Interested in purchasing a fully restored piano? Don’t hesitate to reach out to us at info@chicagoelectricpiano.com!

Comments (4)

-

Amazing!

-

Well done, but repainting it takes away the patina, I would have cleaned and repaired the outer casing, but not repainted, just laquered it – keeping the roadworn vintage look. But I guess there are two schools here…

-

That’s an interesting school of thought, I guess. In the hundreds of Wurlitzers we’ve restored I’ve never had a single person ever request that we lacquer over the scratches and gouges on the bottom of their Wurlitzer in order to preserve the better. Some people opt not to refinish at all, but lacquering over the wear and tear would be a first for us.

-

-

Well done, it looks and sounds great! I’m in the early stages of restoring a 1974 EP200 that was in similar condition (in Australia). I like the truck bed liner finish and might try that 🙂 I’m currently replacing the worn out springs…